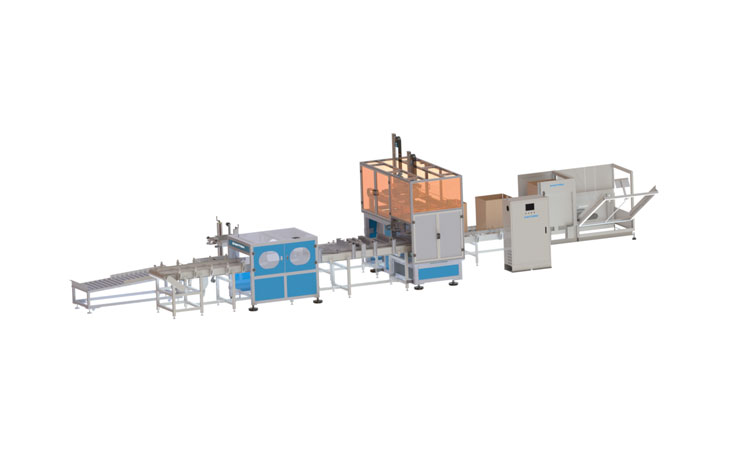

The first bottle caps auto-production system had been successfuly running for more than 100 days, and the second one is ready for assembly.

According to the chief designer of SWITEK bottle caps auto-production system, the new production system integrated units of the bottle caps picking, sorting, ccd inspection and auto-loading. Which will not only help to reduce the man hour during production, but also increase the loading capacity of 400pcs to 2000pcs/carton. With a daily production capacity up to 800,000 pcs, the new system will help to producer reduce 1200 cartons, 8 times 20FCL truck delivery and more than 200cbm storage space. With the reduced carton, shipping and storage cost, the bottle caps manufacturer is expected to recover the investment cost in about 10~12 months. Not to mention the reduced labour cost. Witnessed the profitibility of the new production system, HuiWei Group, the key supplier of Yili & MenNiu, the top cold drink and milk products producer in China, ordered another automation system immediately after the successful trial running of the first production line. Now it's ready for assembly.

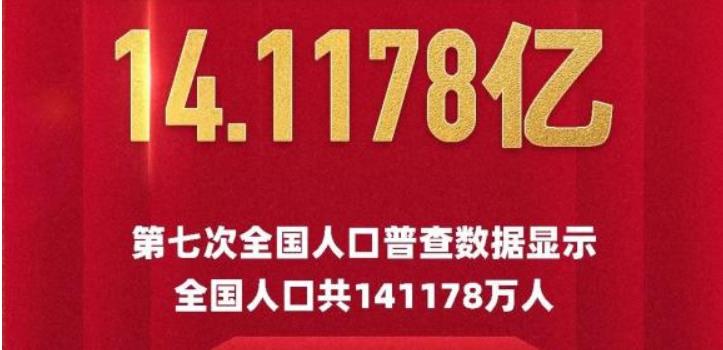

The achievement of "Made in China" attracted worldwide attention in the past 40 years. But at the same time the "labour shortage" is a more and more severe situation to hindle the developemnt of many company especially the labour intensive industry. The young people would rather to choose an office work with a low wage instead of a better paid blue collar job. In this case, it's more and more difficult for the technical school to attract talanted students, which worsen the labour force market further. The labour shortage will not only influence the current production of an enterprice, but also the talents reservation for future development.

Designated to provide our clients a turn key solution of injection molding automation since the founding in 2006, SWITEK is well understand the sorrow of the entrepreneurs of the plastic industry. Since the first IML system put on market in 2009, SWITEK built up a tight relationship with the producers of the thinwall products to custom make an efficient automation solution for their current and future needs. SWITEK bottle cap automation system is a good example for this regard. The automation system integrated the injection robot automation system, CCD inspection system, auto-sorting and loading system, and also the possibility to upgrade the system for Iot application. The new system will not only help to reduce the amount of labour used, but also attract more talents to join the company.

The successful installation of the bottle caps automation system enhanced the confidence of HuiWei Group to cooperate with SWITEK. The new project cooperated between HuiWei and SWITEK will unveil soon at booth # 12.1R21 at Chinaplas 2019. In this new solution, you'll have a better understanding of the up to date IML technology, CCD inspection technology, auto-assembling technology and auto-loading technology. With all these cutting edge technology, SWITEK will help the lids producer migrate from a labour entensive enterprise to an information technology based IoT company.

中文

中文  English

English